Manual Warpage Adjust Tool

The MWAT is a semi-automated warpage correction tool, specifically designed for research and development laboratories or pilot lines during ramp up of a new technology.

Description

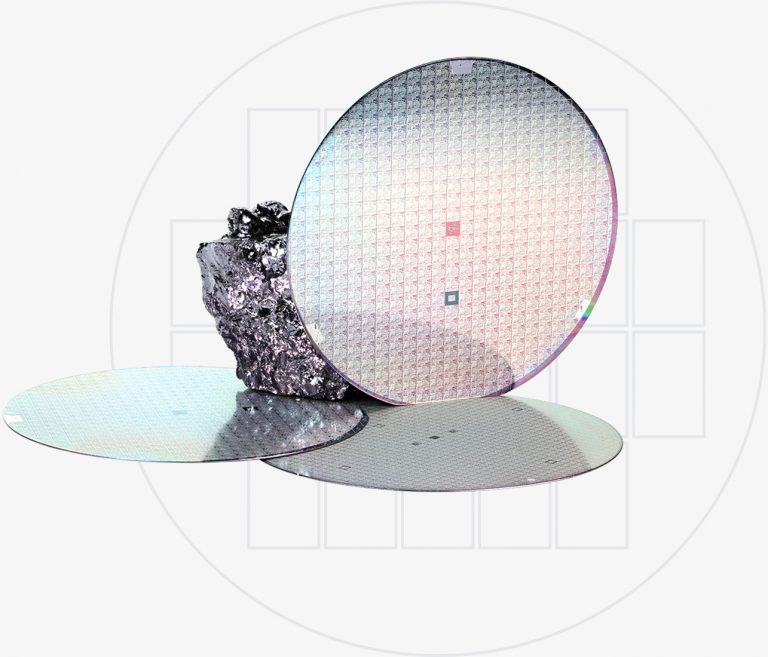

The ERS MWAT System is designed for semi-automated warpage adjustment of a molded, reconstituted wafer, especially in the style of the FOWLP technology but also for similar fan out wafer level package techniques.

It offers a PLC controller with storage capability of more than 100 recipes. The heart of the machine is the proprietary ERS TriTemp Slide. It provides advanced thermal conditioning of the warped wafer in order to significantly and permanently improve the shape of the wafer.

An optional oxygen free TriTemp Slide can be provided for oxidation sensitive wafers, for examples after application of a redistribution layer.

This tool is specifically designed for research and development laboratories or pilot lines during ramp up of a new technology.

Features

- Molded FOWLP wafer warpage control

- Large recipe storage

- Optional oxygen free environment

- MMI with touch screen

MWAT

Technical data

Dimensions

Facility Supply

For special requirements, please contact us.